Freestanding Jib Cranes

Liftsafe Engineering is a trusted provider of complete Jib Crane systems. Working alongside our reliable suppliers, we combine expert service and knowledge to create both standard and custom systems. For our clients, we offer jib cranes in multiple capacities, types, sizes, and options for overhead lifting. These Freestanding Jib Cranes can be portable, wall-mounted, floor-mounted or articulating and are ideal for overhead lifting in a workstation environment. Our jib crane designs offer lifting support for loads ranging anywhere from 100lbs to 30,000lbs, with custom options available. Rely on our in-house engineering, design, fabrication, and installation team to deliver from our comprehensive list of Jib Crane systems.

Light Duty Freestanding Jib Cranes

Workstation Jib Cranes provide easy, ergonomic lifting and transfer of repetitive loads. They are small, nimble cranes that are faster than motorized jibs.

- Crane Rotation: 360°

- Spans: up to 16’

- Capacities: up to 1,000 lbs.

Tool Solutions Jib Cranes were designed to be a durable, lightweight option for applications with suspended tooling or light duty lifting. The small footprint of these cranes makes them ideal to install in small areas, such as between machines.

- Coverage area: 180°/200°

- Span: Circular 4' to 16'

- Capacity: Up to 50 lbs & 150 lbs

Free Standing Work Station Jib Cranes (WSJ360) are Gorbel’s most versatile crane and are best for low capacity, high productivity applications. They are the perfect crane to place in open areas, outdoor applications or in assembly operations.

- Crane Rotation: 360°

- Spans: up to 16’

- Capacities: Up to 1,000 lbs

Heavy Duty Freestanding Jib Cranes

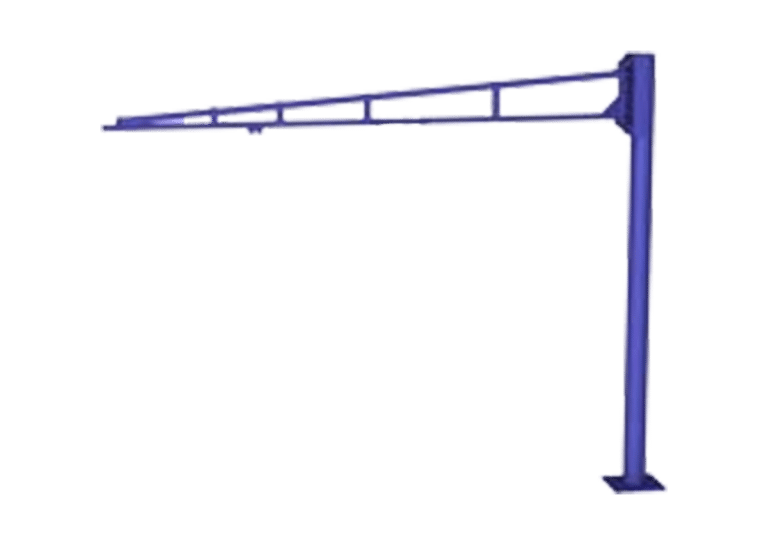

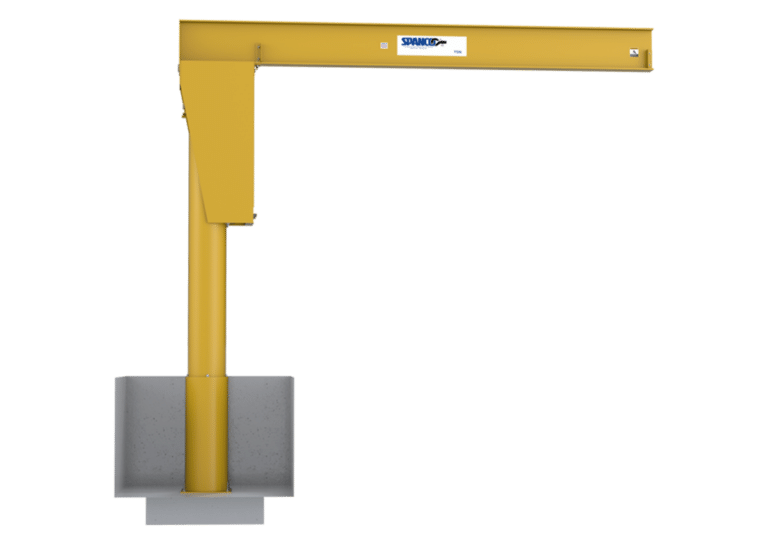

FREESTANDING JIB CRANES - BASEPLATE MOUNTED

The 100 Series Freestanding Jib Cranes, specifically designed for base-plate mounting, offer a straightforward installation process. The base plate is securely anchored using bolts to a specified and reinforced concrete foundation. Depending on the mast diameter, either six or twelve anchor bolts are employed to ensure stability. The mast’s connection to the hexagonal base plate is further reinforced by six equally-spaced gussets, enhancing structural integrity. Notably, these jib cranes are relocatable, allowing for the removal of the entire crane, mast, and base plate, leaving only the footer and anchor bolts in place for added convenience.

- Coverage area:

- Span:

- Capacity: up to 15 tons

Gorbel I Beam Free Standing Jib Crane

The Gorbel Free Standing I-Beam Jib Crane offers versatility with three mounting styles: base plate, insert (permanent), and sleeve (removable). Its boxed style head ensures seamless installation, minimizing deflection with supporting triangular gussets. The enclosed bottom entry collector assembly allows flexible power addition for 360-degree rotation. Enhanced safety features include a robust head retaining pin. Ideal for heavy-duty applications, these jib cranes are perfect beneath large bridge cranes, embodying Gorbel’s commitment to efficient and adaptable crane solutions.

- Crane Rotation:

- Spans:

- Capacities: Up to 10,000 lbs

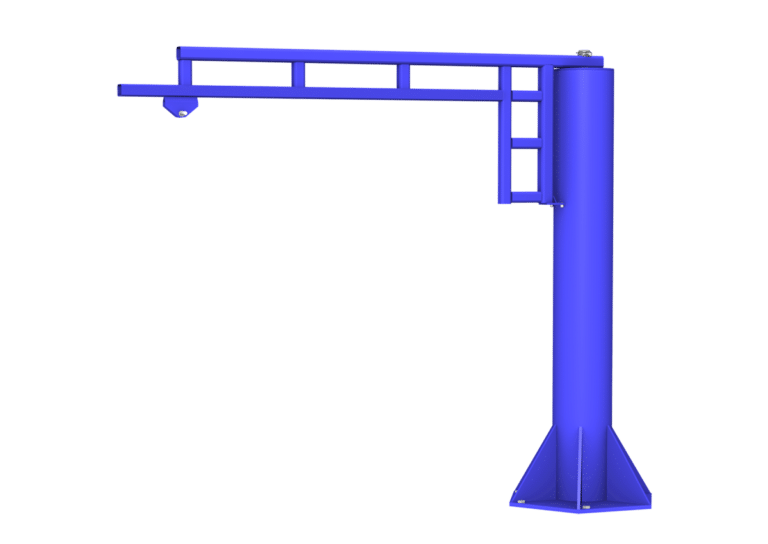

Foundation Mounted Articulating Jib Crane

The 101 Series Freestanding Jib Cranes, designed for foundation mounting, boast a spacious configuration with no gussets, allowing for an unobstructed area at the foot of the mast. The mast is equipped with a square steel plate welded to its bottom, which serves to position and plumb the mast by anchoring it to the first-pour concrete footing. The second-pour of concrete provides additional support for the mast, ensuring stability and reliable functionality. This design feature optimizes space and facilitates a straightforward installation process for these foundation-mounted jib cranes.

- Coverage area:

- Span:

- Capacity: up to 2,000 lbs

Sleeve Insert Mounted ARTICULATING JIB CRANES

The 102 Series Freestanding Jib Cranes, featuring sleeve-insert mounting, offer the advantage of easy relocation without damaging the mast, thanks to the sleeve insert design. With a spacious configuration that eliminates gussets, allowing an unobstructed area at the foot of the crane’s mast, these cranes prioritize convenience. The sleeve is welded to a square steel plate, which positions and plumbs the sleeve by anchoring it to the first-pour concrete footing. The second-pour of concrete supports the sleeve. During installation, the mast is placed into the sleeve, leveled by wedges, and securely welded into place, ensuring a stable and reliable foundation for these versatile jib cranes.

- Crane Rotation:

- Spans:

- Capacities: from 150 to 2,000 lbs.

Your Perfect Solution Awaits!

Customer Portal

Our customer portal reporting system is designed to give you 24-hour access to your reports, certificates and inspections.

Polytainers Overhead Bridge Crane Case Study

Our main concern was being able to safely and efficiently maneuver large molds and dies in and out of injection molding and thermoforming machines.

Crane Inspections and Maintenance

From design to implementation, we offer inspection, maintenance and repair services that span the entire life cycle of your lifting and material handling equipment.

Crane Lifting Systems

Customized systems for every workspace.

In-house engineering team for fast sign-off.

Crane inspection and maintenance available 24/7.

Top-grade components meet all CMAA and CSA standards.

CWB qualified welders, meeting all quality control measures.

Cost-effective material handling solutions.

Improved productivity of the facility.

Access preventative maintenance plans to avoid safety and compliance violations.

Consult a crane specialist

We design, build, inspect and maintain.

GH Cranes & Hoists

Liftsafe is a leading supplier of GH products in Canada, offering premier industrial lifting equipment.

Customer Portal

Our customer portal reporting system is designed to give you 24-hour access to your reports, certificates and inspections.

About Liftsafe

We focus on creating turnkey solutions that allow your employees to do their jobs safely while protecting your company.